The Of American Plastics

Wiki Article

Rumored Buzz on American Plastics

Table of ContentsAn Unbiased View of American PlasticsGetting The American Plastics To WorkUnknown Facts About American PlasticsSome Of American PlasticsThe Only Guide for American Plastics

If no steel wire was installed above the plastic pipe, ground-penetrating radar or acoustical vibration may be utilized. HDPE pipe need to be pressure checked according to PPI suggestions, (NOTE: various other bell and faucet pipelines are checked in a different way than HDPE i.e. allowable leakage rates of bell and spigot versus development of PE) For detailed information on this topic, describe Phase 2 of PPI's Handbook of Polyethylene Pipe, second ed.When HDPE pipe gets in or departures a manhole it is best to utilize a link-seal or a water quit (likewise referred to as a puddle flange) with securing cement. The link-seal or water stop will avoid water from leaking in between the pipeline and grout. https://blogfreely.net/americanplastics/why-choosing-high-quality-hdpe-pipe-matters-insights-from-american-plastics. This depends upon a number of variables such as a contrast of the used inner operating pressure versus the exterior pressure from feasible outside loads, including planet loading, hydrostatic loading and superimposed loading

When water freezes strong in a HDPE pipeline, it will certainly not rupture it, yet the pipe will certainly increase with the ice. Undoubtedly, the application of heat to the icy section is actually the only functional means to thaw it. But also for safety and security factors to consider, and to prevent damage to the pipe, this must be done very thoroughly.

More About American Plastics

This includes covering the damaged area with stress sensitive metal tape over which is covered temperature level restricted (120oF optimum) heat mapping tape. The metal tape assists disperse warmth uniformly over the pipe surface area. Warm blankets are likewise offered, nevertheless lanterns or arc welders ought to not be used to thaw HDPE pipe.Marking to a maximum deepness of 10% of the pressure pipeline wall surface thickness is typically bearable. custom hdpe pipe manufacturing Midland TX. AWWA M55 specifies that "minor scrapes or scuffing will not impair serviceability". It additionally specifies that "pipe with gouges or cuts in unwanted of 10 percent of the product wall thickness should not usually be used"

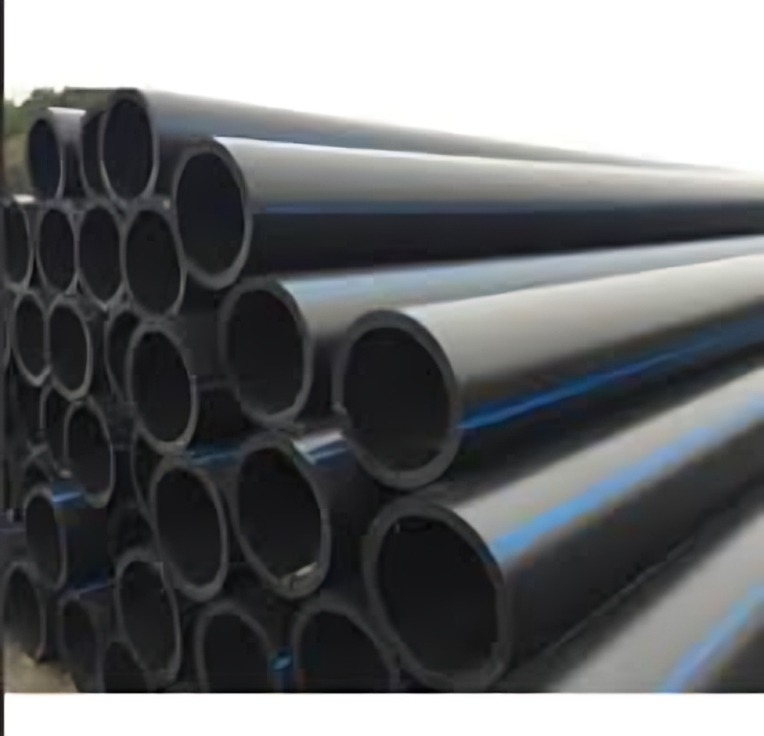

For a succinct appearance at applications, below are some of the most typical kinds of HDPE piping and their applications. Piping systems make use of PE 32 or PE 40 for low-pressure applications.

The 45-Second Trick For American Plastics

PE 80 has a product immune to fractures, so it appropriates in applications vulnerable to cracking, like sewer system and water circulation lines. PE 100 is likewise resistant to fractures, and 100 N/mm2 is the minimum needed stamina. As mentioned, classifications of HDPE piping consist of small pressure, material, and shade coding.Makers produce pipes with different stress grades (PN grades). This shows the stress in bars the pipe can sustain with water at 68 levels Fahrenheit. The stress grades adhere to European criteria, and they are: PN 2.5 max stress 2.5 bar PN 4max stress 4 bar PN 6max stress 6 bar PN 10max stress 10 bar PN 16max pressure 16 bar The shade codes that indicate the pressure grade are yellow for PN4, red for PN6, blue for PN10, and green for PN16.

Colors can vary depending on the country. Strong black for industrial applications Blue or black with blue red stripes for drinking water Yellow or black with yellow stripes for gas channels HDPE pipe dimensions range from small sizes for domestic use to large diameters for industrial and community applications.

Suppliers identify the dimension of the pipe by its interior size and gauge them in millimeters. When selecting the appropriate dimension of HDPE pipeline, think about the volume of fluid you require to carry, the predicted pressure the fluid encounters, and the length of the pipeline. The total list of sizes is extensive.

What Does American Plastics Mean?

Industries consider nominal pressure, product, and other parts when establishing which pipelines to make use of. Industries make use of PN 10 grade HDPE pipeline for water supply and circulation networks.It's worth keeping in mind that gas calls for high tolerance to pressure, making PN-16 to PN-2 grade pipelines suitable for operations. The farming industry uses HDPE pipelines for watering and water drainage. Furthermore, HDPE matters for sewage, mining, and the telecommunications market. Many thanks to piping, cities can handle sewer and stormwater to prevent flooding.

Mining business make use of pipelines for slurry transport and dewatering. Industries choose HDPE piping over conventional pipes due to the fact that they provide a lot more advantages.

American Plastics Can Be Fun For Everyone

For starters, HDPE pipelines are remarkably long lasting and can last a long time with marginal upkeep. They're likewise resistant to deterioration, chemicals, and UV rays. HDPE pipes are likewise cost-efficient compared to various other piping materials. They're much less prone to damage, which cuts repair work costs! HDPE pipelines are lighter than traditional pipes for better handling and transportation.Report this wiki page